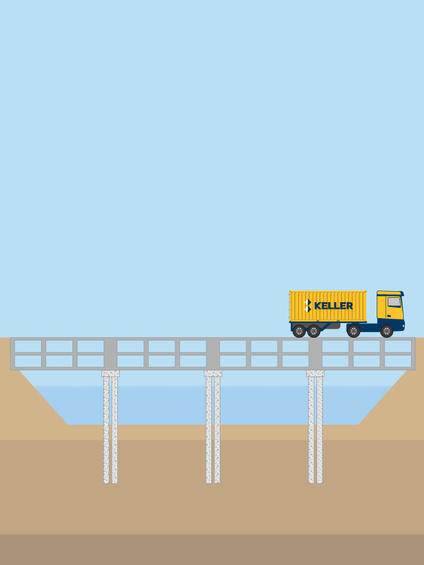

A bridge crossing a body of water creates difficult conditions for the construction of its foundations. Keller can use various techniques to meet the challenges according to the soil, environmental impact assessment, current and water depth.

Common uses

Process

A number of different processes can be used to install piles for bridge construction and repair.

If executed from a barge, the first step is to install a temporary casing, vibrated into the bottom of the body of water to the depth at which it will be sufficiently stable. A large diameter drill rig will then excavate the pile. Executing foundations from a barge has little impact on the environment.

Alternatively, a Reverse Circulation Drilling (RCD) rig can be installed on top of the casing to drill the pile, with a high flow pump removing the excavated soil with the drilling fluid. A desander plant then separates the soil from the fluid so it can be recycled. This approach enables execution of very large diameter piles in almost any ground conditions.

If there’s no environmental impact, another option is to first build a temporary bund or embankment in the water and create a cofferdam. This enclosure built within a body of water allows the enclosed area to be pumped out. Foundations can then be executed as if onshore using a range of techniques including:

- Barrettes, executed either by grab, hydraulic grab or cutter, with a very high load bearing capacity

- Bored piles (up to 2.4m diameter)

- Soilcrete, a very versatile solution that can be adapted for most issues

For larger projects, caissons may be more cost-effective. Here the bottom of the body of water is improved by vibro-compaction or the execution of vibro stone columns below the water. After levelling of the subsea surface, the caisson is then set onto the improved area.

Depending on ground conditions, vibro compaction can improve the soil conditions without the addition of any other material. And our state-of-the-art equipment for subsea columns can install and vibrate the stones exactly where they are needed with substantial savings on material.