Rotapiles uses down-the-hole (DTH) air driven hammer to advance casing during drilling, specifically for penetration through boulder profiles or hard rock socketing.

Common uses

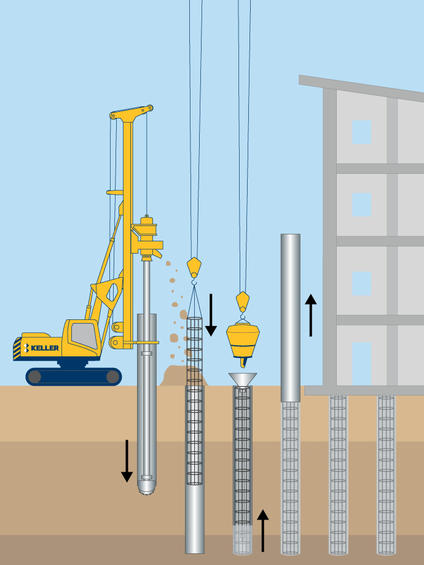

Process

Down the hole (DTH) hammers are used to advance casing and penetrate the overburden soil. Once rock is reached the socket can be drilled uncased. The pile hole is flushed clean before full length cage is placed and the pile is grouted from the base with a tremie pipe. The casing can be removed after grouting or left in place and incorporated into the pile design. Pile diameter up to 600mm is typically available with capacities up to 3500kN.

Advantages

Quality assurance

We use a variety of quality assurance methods for our products including top down and integrity testing and recording and logging of the execution parameters.