SA Builder Magazine - September 2022

Solving tricky geotechnical challenges for new developments is one of Keller’s core strengths. Doing it in record time is one of its core abilities. The new expansion at the Fruitways Molteno packhouse facility in Grabouw is a prime example of this. The site for the new 1 150m² cold storage warehouse is underlain by a 3m-thick layer of clayey silt, which is certainly not conducive to using traditional foundation techniques. This challenge called for a specialised foundation solution.

The Keller design team, led by technical director Dr Nicol Chang, quickly assessed the settlement criteria and the ground conditions to come up with an efficient foundation for the new cold storage packhouse. This fast-tracked project demanded an innovative solution that would meet the timeline, the budget and, of course, the stringent settlement performance criteria required for modern-day warehouse developments. “Fruitways will be deploying an automated mobile racking system four pallets high. Any settlement would have disastrous effects on the racking, product and structure,” says Jacques Esterhuizen, Fruitways’ general manager: engineering.

Keller’s rigid inclusions (RIs) ground improvement technique ticked all the boxes.

RIs are a relatively new offering to South Africa and highlight Keller’s commitment to bringing reliable, industry-leading techniques to our region.

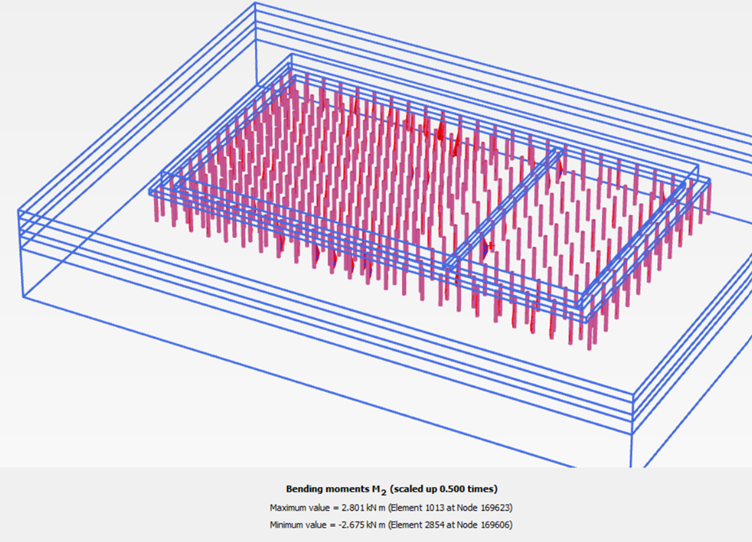

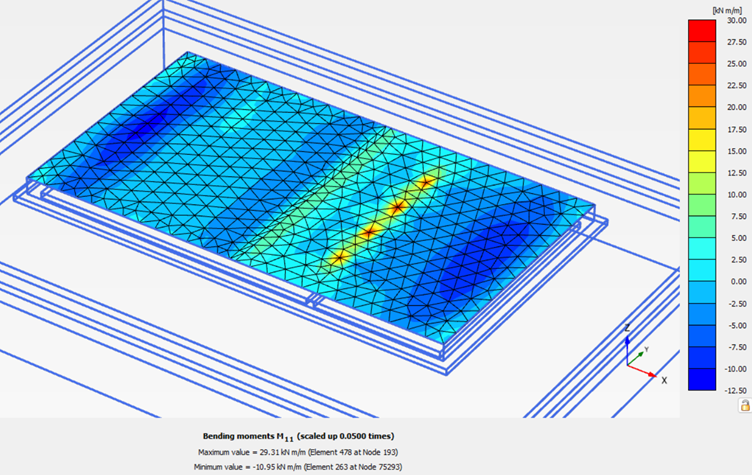

Examples of detailed FEM analysis done during the design stage

GEOLOGY AT THE FRUITWAYS MOLTENO SITE

The ground investigation was done by Frank du Plessis of consultants Kantey & Templer. Geologically, the site is situated in terrain composed of and underlain by meta-sedimentary siltstone/mudstone/shales of the Ceres Formation, Bokkeveld Group, Cape Supergroup.

The site is covered by a layer of fill up to 0,9m. Transported soils comprise very soft, clayey silt up to 3,0m underlain by residual shale grading to very soft rock shale.

The very soft, clayey silt is highly compressible and problematic for the settlement-sensitive structure if shallow foundations are used. Traditional piling methods require significant modifications in the structure, which may cause delays in this already fast-tracked project.

PRINCIPLES OF RIGID INCLUSIONS

The design approach for RIs is quite different from that taken for a typical foundation or piled solution.

With RIs, a grid of ground columns is installed under the footprint of the entire structure. These “ground columns” are then covered with an engineered fill, forming a load transfer platform (LTP).

Load from the structure is transferred and distributed into the soil via this LTP. The depth of the LTP is a function of the spacing of the RIs.

The ground improvement efficiency of an RI solution largely depends on the stiffness relationship between the soil and the columns.

PROVEN METHOD

RIs are a proven method to reduce settlement and increase the bearing capacity of weak soils, even for high loads. The installation is relatively quick and generates minimum spoil, allowing a quick start to construction works. RIs are essentially a ground improvement method using high modulus columns constructed through compressible soils to reduce settlement and increase bearing capacity.

QUICK AND EASY

The new cold storage warehouse development is a fast-tracked project planned to be completed within a relatively short period for the next fruit season. The project, led by industry specialist consultant Gerhard Potgieter from GPB Consulting, broke ground on 1 August and is due for completion in Q1 2023. “All in all, the RI solution provided by Keller was a good fit for our project,” says Esterhuizen. “The RIs were quick and easy to install, providing a solid foundation for the new cold store. We have confidence in Keller’s technique and ability to deliver this project in good time and meet expectations.”

The Keller site team, led by works manager Shaun van der Westhuizen and foreman Cedric Makhubela, installed a total of 360 RIs within 10 days, including establishing to site.

BENEFITS OF THE RI SYSTEM

One of the main benefits of using RIs is that once the ground has been treated and improved, traditional shallow foundations can be used to support the structure, without any further design changes to the structure. For the Fruitways project, this was certainly the case. Keller worked closely with structural engineers ABRI, which embraced the new technology and adapted to the RI solution with ease. “This was the first time we used RIs as a foundation solution,” says director André Burger.

TURNKEY DESIGN AND CONSTRUCT SERVICE

Solid support for warehouse floors is often underestimated, particularly when modern stacking and racking systems demand tight tolerances. Keller is proud to be part of the prestigious Fruitways project, which highlights the overall capability of its team, from design to installation. The company is able to deliver a complex turnkey design and construct service for all projects requiring specialist geotechnical services.

Completed platform areas on the left and newly-installed RIs on the right

Article by Roger Feldmann