The authoritative new report by the Intergovernmental Panel on Climate Change sets the world a clear target: we must reduce emissions of greenhouse gases (GHG) to net zero by the middle of this century to have a reasonable chance of limiting global warming to 1.5°C.

To achieve emissions targets, annual emissions will need to fall by about 50% between now and 2030 and reach net zero by 2050. A similar target was recently announced by US President Joe Biden for the United States to achieve a 50% reduction in GHG emissions from 2005 levels by 2030.

GHG EMISSIONS IN THE BUILDING AND CONSTRUCTION INDUSTRY

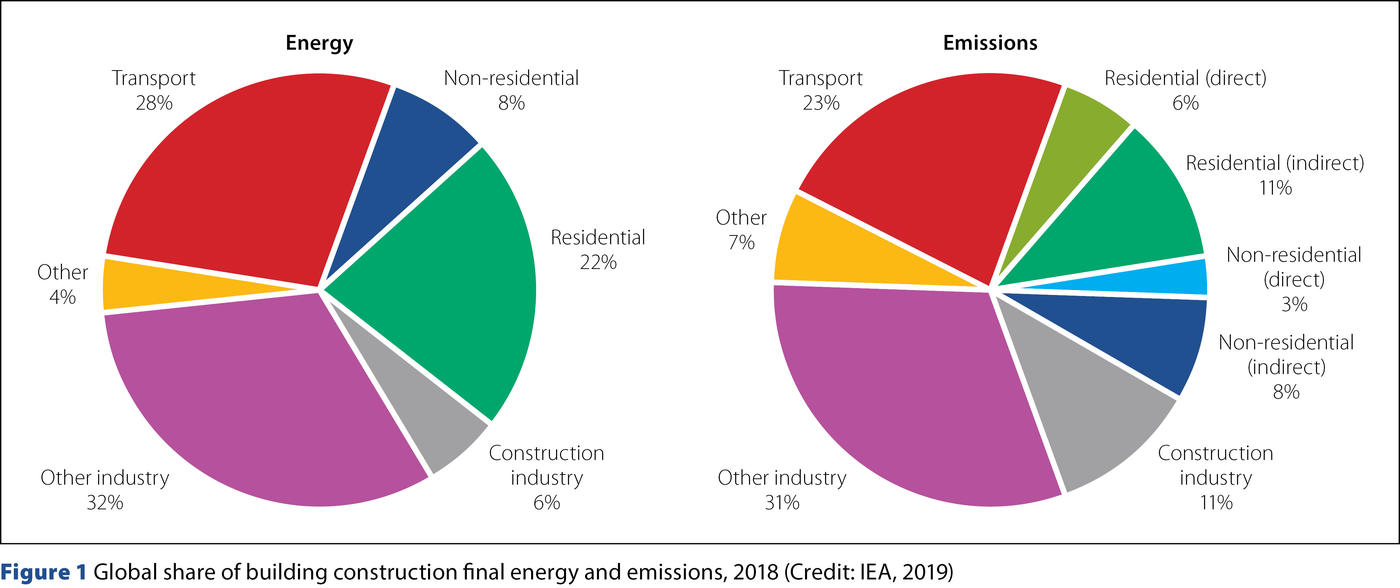

According to the United Nations 2019 Global Status Report for Buildings and Construction, building construction and operations accounted for 36% of energy use and 39% of CO2 related emissions in 2018.

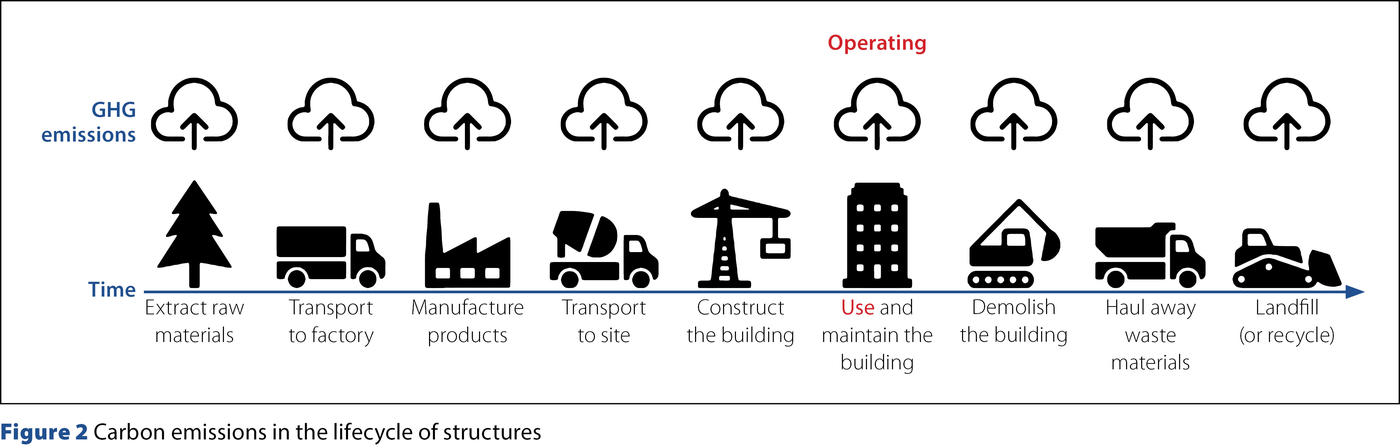

The emissions produced in the building sector is made up of two components. The first is emissions arising from operation of the building, which account for approximately 30% of global emissions. The second component, embodied emissions, consists of all the GHG emissions associated with building construction, including those that arise from extracting, transporting, manufacturing, and installing building materials on site, as well as the operational and end-of-life emissions associated with those materials. Embodied emissions account for approximately 10% of global emissions.

The building sector is the single largest sector generating CO2 emissions which can be traced throughout the life of the building, from extraction of raw materials to the demolition and disposal of waste material at the end of the structure’s service life. It is therefore important to evaluate emissions from buildings as part of the design and evaluation process to make meaningful progress towards reducing or negating emissions from buildings.

CARBON EMISSIONS IN GEOTECHNICAL CONSTRUCTION

Emission sources are grouped into seven categories: materials, energy, freight, mobilisation, transportation, asset and waste. A brief description of each category is given below:

• Materials – related to manufacturing of materials used in construction e.g. cement, steel, additives

• Energy – related to energy used on site e.g. diesel for equipment, electricity for running offices

• Freight – related to transportation of construction materials

• Mobilisation – related to transportation of major equipment

• Transportation – related to transportation of people

• Asset – related to manufacturing of equipment

• Waste – related to transport and disposal of waste produced.

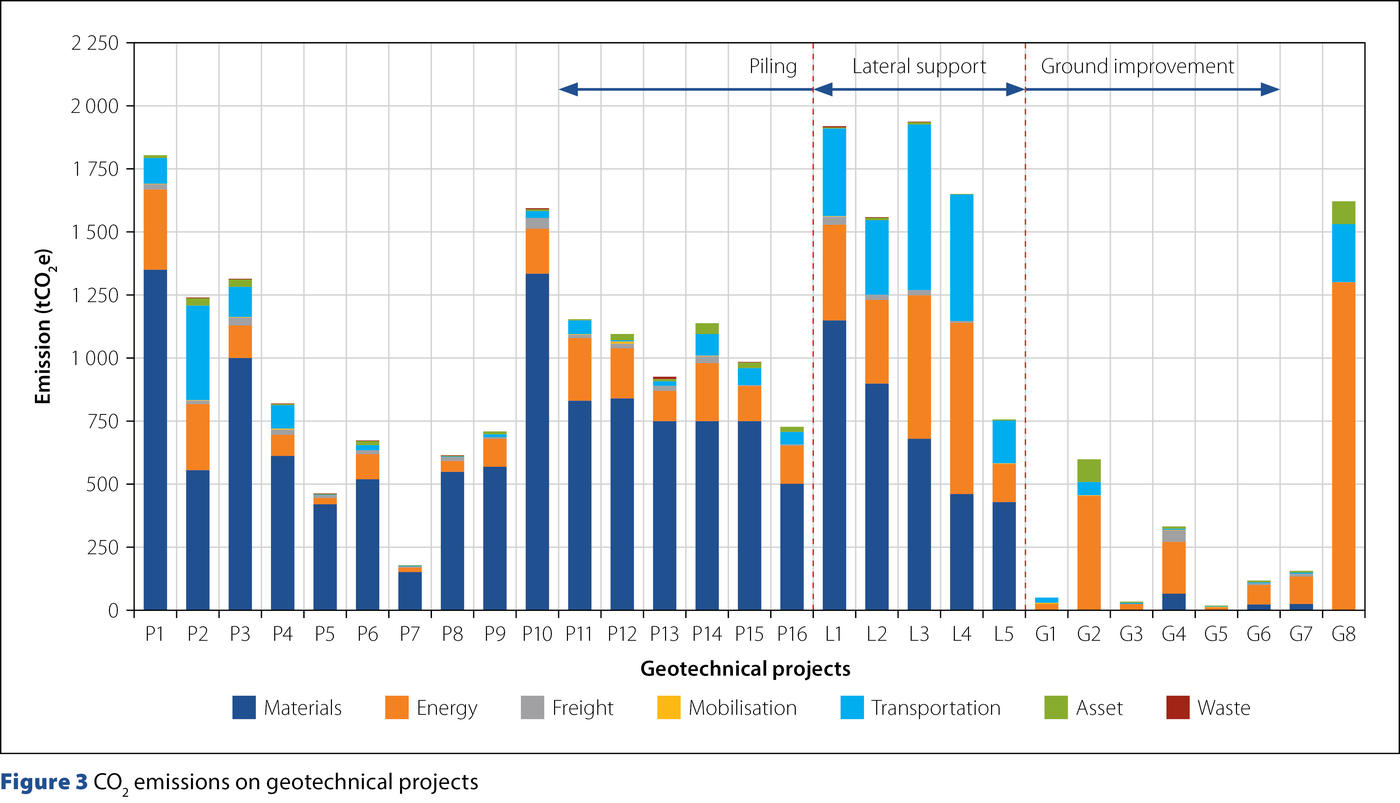

Emissions have been evaluated for various geotechnical projects involving piling, lateral support or ground improvement works, as summarised in Figure 3.

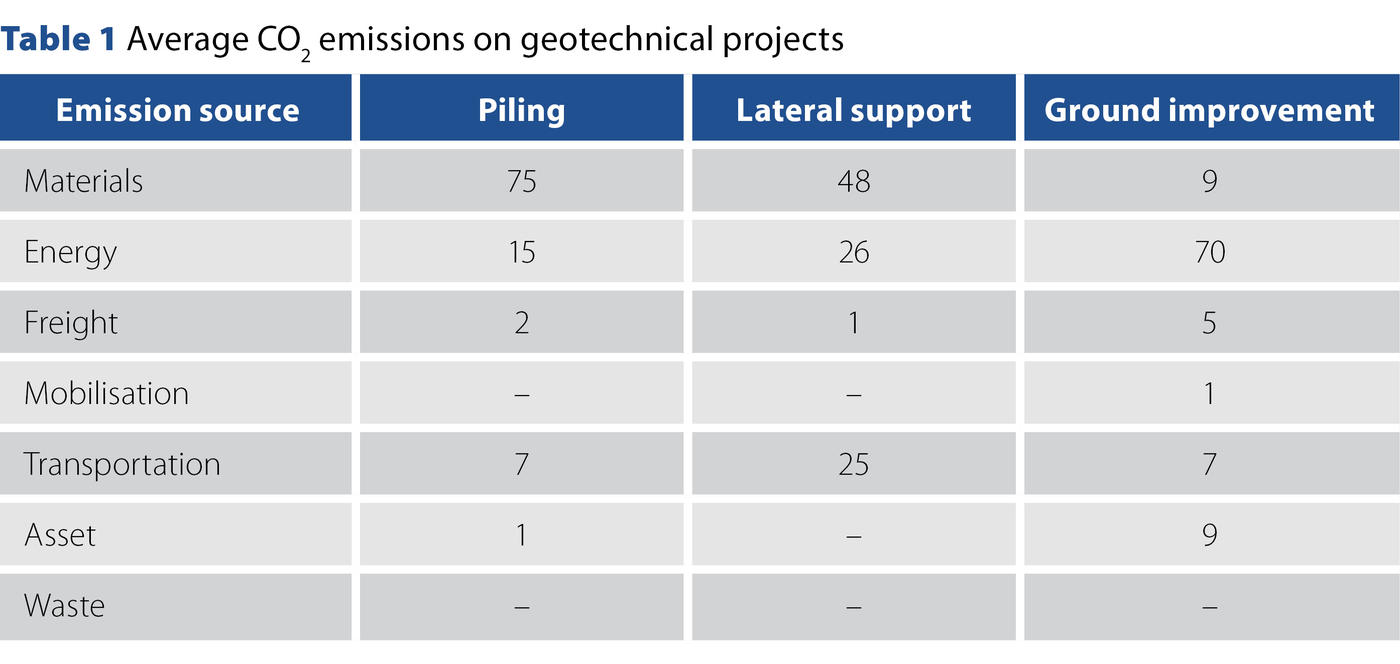

Although these projects are of various sizes, it does provide an understanding of the main emission sources for various types of geotechnical products. The average CO2 emissions from the three product categories is given in Table 1.

Emissions for piling projects are mainly derived from the materials used in construction, accounting for, on average, 80% to 90% of emissions on piling projects. Emissions from the materials category can be further broken down into cement (83%), aggregates (2%) and steel (15%).

Emissions from lateral support type projects are also dominated by materials, but to a lesser extent than piling type projects, with a range of 30% to 60% of total project emissions. Lateral support systems which make use of piles (such as contiguous or secant pile walls) generate emissions closer to the upper value of this range, whereas systems which don’t include piles (such as soil nails or micropile walls) generate emissions closer to the lower value of this range. The balance of emissions is generated, approximately equally, from energy and transportation sources.

In contrast to piling and lateral support, emissions on ground improvement projects are dominated by energy usage, accounting for 50% to 80% of total project emissions.

REDUCING EMISSIONS FROM GEOTECHNICAL PROJECTS

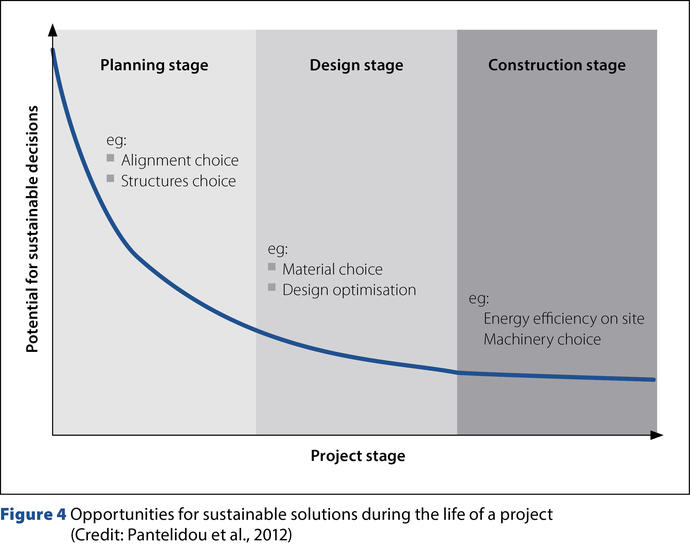

Geotechnical engineering is an important part of civil engineering and the construction industry, providing an interface between human society and the surrounding environment. According to Pantelidou et al. (2012), the opportunity for sustainable solutions is highest during the initial stages of the project. Geotechnical engineering, typically positioned at the inception stages of projects, provides excellent opportunities for sustainable solutions.

Carbon emission can be reduced in four ways:

1. Completely eliminate sources which emit carbon dioxide

2. Reduce emissions through optimised design, improved operational efficiency, etc.

3. Substitute by using recycled or recyclable material

4. Compensate through negative carbon solutions.

Cement is a major contributor of emissions in construction. For piles, which consist mainly of concrete and steel, the common interventions would be to reduce the cementitious content by substituting with blast furnace slag (GGBS) or fly ash. Production of one ton of cement produces around 800kg to 900kg of CO2 per ton compared to GGBS which generates 80 kg CO2 per ton. Fly ash is a byproduct of burning coal and has no linked emissions.

For steel reinforcement, using recycled steel can reduce CO2 emissions from approximately 2000kg per ton to 500kg per ton.

GROUND IMPROVEMENT AS A SUSTAINABLE ALTERNATIVE TO PILING

Ground improvement is one way to eliminate or reduce cement usage in foundation construction. In the South African context, ground improvement is synonymous with dynamic compaction. There are, however, many other methods available for foundation construction, such as vibro compaction, stone columns, rigid inclusions, soil mixing and vertical drains.

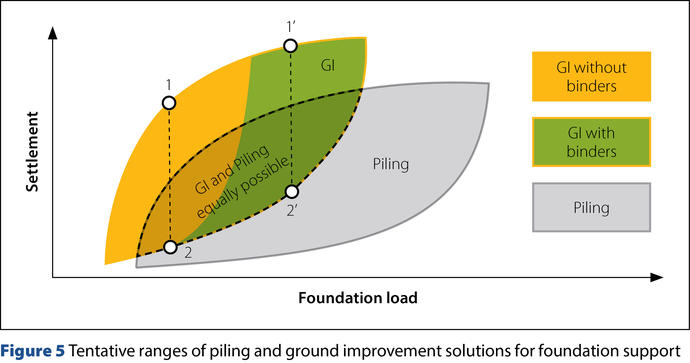

Most consultants consider ground improvement only applicable for light structures and maintain that for heavy structures, piled foundation should be used. Topolnicki and Chang (2019) have demonstrated that there are some common applications where both solutions are feasible, which they illustrated with numerous case studies. Ground improvement solutions often have an added cost and programme benefit, but for practical implementation, it is important that ground improvement solutions be considered at the conceptual design stage of the project.

CONCLUDING REMARK

Tesla is transforming the car industry by introducing energy-efficient electric vehicles. Apple, Google, Amazon and Microsoft are moving to renewable energy to power offices and data centres. As companies around the world rapidly innovate to reduce their impact on the environment, the construction industry in South Africa has an opportunity to make our contribution.

REFERENCES

IEA. 2019. Global Status Report for Buildings and Construction: Towards a zero-emission, efficient and resilient buildings and construction sector. Global Alliance for Buildings and Construction (GlobalABC), International Energy Agency (IEA), and UN Environment programme.

Pantelidou, H., Nicholson, D., and Gaba, A. 2012. Sustainable geotechnics. In Manual of geotechnical engineering. Vol. 1. Institute of Civil Engineers, UK.

Topolnicki, M. & Chang, H.N. 2019. Ground improvement, an alternative to pile foundations, Proceedings, 17th ARCSMGE, Cape Town, 2019.

Article written by Dr. Nicol Chang Pr Eng, Technical Director, Keller Middle East Africa - nicol.chang@keller.com