Use of rigid inclusions to overcome challenging ground conditions at Clairwood Logistics Park.

Construction on soft clays has always posed a great challenge for the geotechnical engineers. Soft clay is characterized by low strength, stiffness and permeability which leads to long term settlement related problems if foundations are inadequately designed.

Large parts of the Durban area are underlain by estuarine deposits consisting of lenticular sand deposits intercalated with silts and clays overlain by thick layers of dark grey, soft silty clay. As the deposit is extremely variable, both spatially and in its engineering properties, construction over these deposits is extremely challenging, often resulting in conservatively design and expensive piled foundations.

A foundation solution was required for the 350 000sqm Clairwood Logistic Park Development, located on the old Clairwood Racecourse approximately 3km north east of the old Durban International Airport. The site is underlain by soft clays extending to depths of 35m and traditional piled foundations are financially not feasible. The proposed solution was ground improvement with the use of rigid inclusions or Controlled Stiffness Columns (CSC®).

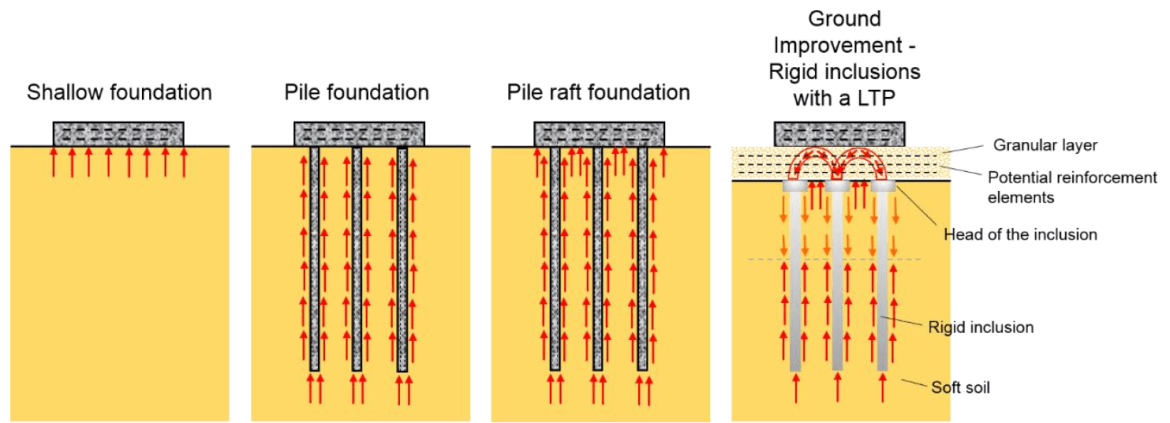

The principles of ground improvement with rigid inclusions requires concrete columns to be installed in a grid format and founded on rock or a competent soil layer. These concrete columns do not necessary improve the mechanical properties of the clay but reinforces the soil to create a composite soil/concrete mass with significantly improved mechanical properties. The system also requires a load transfer platform (LTP) constructed above the column head to transfer load from the structure to the rigid inclusions, similar in function to a pile cap which transfers load from the column to the piles. The difference in operating principle, in comparison to other foundation systems, is summarized in Figure 1.

Keller (then Franki Africa) was awarded the ground improvement works for the Clairwood Logistics Park development in late 2016, which included installation of over 45000 rigid inclusions to depths of over 35m. The work scope included site characterization, design, implementation, control and monitoring of the ground improvement system. Bigen Africa, assisted by SRK Consulting Engineers provided independent review and control of the geotechnical works and as well as interface between the geotechnical and structural design.

Installation of rigid inclusions will be carried out by Liebherr LRB 255 crawler rigs specially equipped with model 32 VMR ring vibrators to drive temporary steel tubes to the required depths. The use of the vibratory driving method also allows the rigid inclusion lengths to be installed based on the actual ground condition/profiles rather than to some designed depth which may be inadequate or over-conservative in highly variable ground conditions.

The rigid inclusions were finished with a gravel head installed using Keller Vibrocats (Figure 3) and topped with 2-3m engineered fill which acts as the load transfer platform. The combination of rigid inclusions and gravel head, also known as a Hybrid Column (CMM®), reduces the risk of column head damage by construction vehicles or the environment and reduces the punching stresses and moments on the floor slabs.

To date Keller has executed over 30 000 CMMs to support various structures on the Clairwood site. Settlement cells were installed on the first fully constructed platform to monitor the operational settlement. These results were published by Chang (2019), with differential settlement of less than 10mm measured over plan distance in excess of 100m.

Ground improvement with rigid inclusions has numerous advantages compared to conventional piled foundations, particularly in challenging ground conditions. As with all ground improvement techniques, structures are founded on inexpensive light/shallow foundations once the ground improvement is complete. This generally leads to significant reduction on the cost of the overall foundation system when compared with piled solutions which requires pile caps, ground beams and significantly thick rafts or slabs. Installation of rigid inclusions are significantly faster than conventional piling, particularly in challenging soil conditions, and often leads to program and cost benefits for the project. Furthermore, the inherent redundancy in ground improvement solutions provides reduced risk in challenging ground conditions (in ground characterization, design and implementation) when compared to piled foundations which provides the full resistance for the structure. Lastly, as with most ground improvement solutions, carbon emissions are significantly reduced.

It is a cost-effective alternative to piling for structures over large footprint with distributed loads such as warehouses, storage reservoirs, treatment plants, basins and retention facilities, road embankments etc. which often have stringent differential settlement criteria.